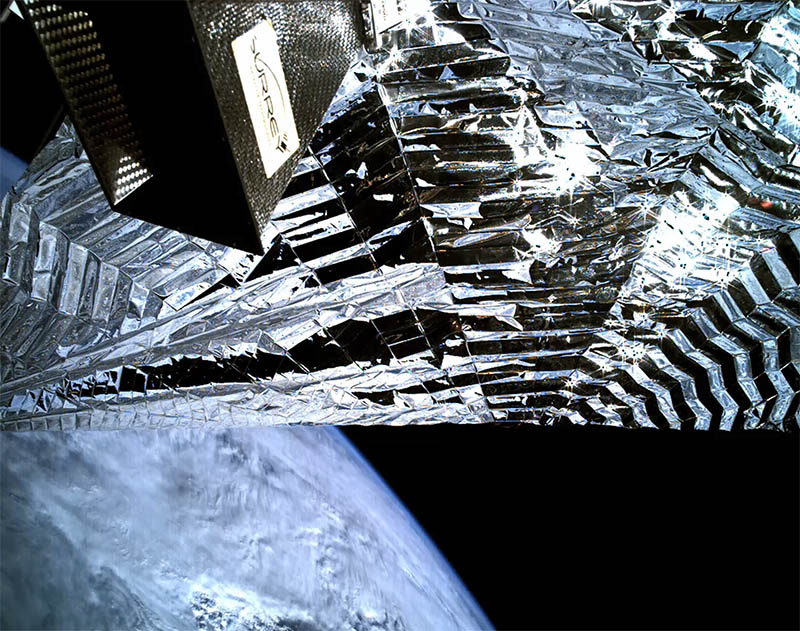

Surrey Satellite Technology Ltd (SSTL) has released an image showing the successful deployment of the de-orbit drag sail on-board TechDemoSat-1. The deployment of the Icarus-1 drag sail, which was supplied by Cranfield University, marks the end of mission operations for SSTL’s TechDemoSat-1 small satellite which was launched into a 635 km Low Earth Orbit in 2014.

Sarah Parker, Managing Director of SSTL, said “It is fantastic to see an image of TechDemoSat’s deployed drag sail captured by the onboard inspection camera. This in-orbit image of a deployed drag sail on one of our satellites is a first for us and is a fitting culmination of mission operations for this highly innovative small satellite.”

TechDemoSat-1, a 150 kg in-orbit technology demonstration small satellite mission, validated 8 innovative UK spacecraft instruments and software payloads and also acquired ocean wind speed datasets using GNSS reflectometry.

The deployed sail measures approximately 6.7 m2 and is designed to significantly increase the spacecraft’s rate of orbital decay, in compliance with current Space Debris Mitigation best practice and guidelines.

Stephen Hobbs, Head of Cranfield University’s Space Group, commented “At Cranfield we are delighted to see our Icarus de-orbit technology demonstrated successfully in orbit – again. With the Icarus sails now deployed on both TechDemoSat-1 and Carbonite-1, SSTL and Cranfield have demonstrated clear leadership in this technology. We hope to see many more satellites following TechDemoSat-1’s example to keep space clear of debris. It’s been great to work with SSTL on this mission.”

The Icarus-1 drag sail consists of a thin aluminium frame fitted around one of the external panels of the spacecraft in which four trapezoidal Kapton sails and booms are stowed and restrained by a cord. Deployment is achieved by activating cord-cutter actuators, allowing the stored energy in the spring hinges to unfold the booms and the sail.

The inspection camera on-board TechDemoSat-1 was manufactured by SSTL’s optics experts from COTS (Commercial-Off-The-Shelf) technologies and combines a colour CMOS camera with a high performance machine vision lens delivering 1280 x 1024 resolution imagery and a field of view of 65 x 54 degrees. The camera previously captured footage moments after separation from the Fregat upper stage of the Soyuz-2 launcher, as the satellite began its first orbit in space.

SSTL is at the forefront of space debris mitigation and removal activities and is the satellite platform manufacturer and spacecraft operator for the RemoveDEBRIS mission, and the supplier of the Target satellite for ASTROSCALE’s ELSA-d end-of-life spacecraft retrieval and disposal technology demonstration mission.

TechDemoSat-1 was part-funded by Innovate UK and was jointly operated by SSTL in Guildford and by the Satellite Applications Catapult in Harwell.

The spacecraft carried eight separate payloads from UK academia and industry, providing valuable in-orbit validation for new technologies:

• MuREM, a flexible miniature radiation and effects monitor from Surrey Space Centre

• ChaPS, a prototype compact instrument to detect electrons and ions from the Mullard Space Science Laboratory

• HMRM, a lightweight, ultra-compact radiation monitor designed to measure total radiation dose, particle flux rate and identify electrons, protons and ions from Rutherford Appleton Laboratory and Imperial College

• LUCID, a device to measure characterisation of the energy, type, intensity and directionality of high energy particles from the Langton Star Centre

• Compact Modular Sounder system, a modular infrared remote sensing radiometer unit from Oxford University’s Planetary Group and Rutherford Appleton Laboratory

• De-orbit sail (Icarus-1 mentioned above) from Cranfield University

• Cubesat ADCS, a 3-axes attitude determination and control subsystem from SSBV

• Sea State Payload, a device using an enhanced GPS receiver from SSTL and components from a Synthetic Aperture Radar from Airbus Defence and Space to monitor reflected signals to determine ocean roughness.